![]() Types of Occupational Hazards

Types of Occupational Hazards

1. Physical hazard in the workplace

Noise, insufficient illumination, excessive vibration or prolonged vibration exposure, extreme temperature (both hot and cold), ionizing radiation, or non-ionizing radiation are all physical risks.

2. Chemical hazard in the workplace

It may include exposure to toxic compounds or allergies in the form of dust, mist, vapour, gas, fumes, solid, or liquid. Exposure can occur through direct contact with the skin, inhalation, or ingestion.

3. Biological hazards in the workplace

It includes exposure to viruses, bacteria, and fungus via direct skin contact, inhalation, or ingestion, and can result in acute or chronic infection or disease.

4. Occupational psychological health risk

Lack of job happiness, instability, poor interpersonal interactions, work pressure, stress, and ambiguity are all psychological dangers. Hostility, aggression, anxiety, despair, alcoholism, drug addiction, and sickness absenteeism are all examples of psychological and behavioural changes.

5. Occupational health danger from mechanical equipment

This type of hazard is caused by an improperly planned workplace or work task. Repetitive job movements, such as lifting, holding, carrying, lowering, loading, walking, and so on, can produce occupational workplace hazards.

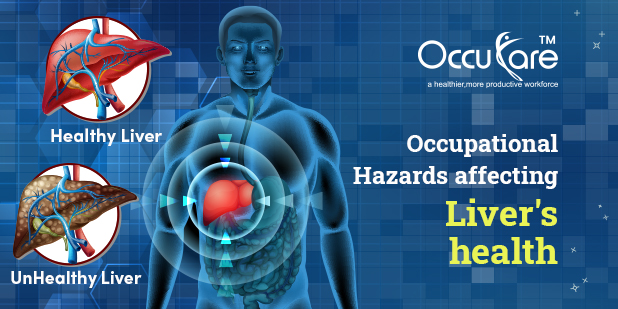

How might an occupational hazard harm the liver?

Almost all chemicals and medications that enter the bloodstream are processed by the liver, and substances that are difficult for the kidneys to excrete are removed. Because of the liver’s role in detoxification, it is very sensitive to toxicity, and occupational contact to toxins should be avoided. Hepatotoxins are chemicals that have been shown to harm the liver.

Toxins that can harm the liver have been classified into two categories:-

Toxins with Predictable Effects

Toxic hepatitis and liver damage are known to occur after prolonged exposure to one or more of these substances. Cleaning solvents, carbon tetrachloride, and the pain reliever acetaminophen are examples of compounds in this category.

Toxins that are Unpredictable

Toxins that are unpredictable cause liver harm in a very tiny percentage of those who are exposed to the chemical. Most medications cause unpredictable harm, but recent results suggest that a toxic response to a substance is likely to depend on the type of enzyme a person inherits to digest the drug.

Industrial chemicals, medications, some bacterial and viral diseases, and other physical agents are examples of occupational and environmental toxins linked to liver injury. Chemical agents that produce liver harm as a result of host idiosyncrasy are classed as direct hepatotoxins, indirect hepatotoxins, or agents that cause liver injury as a result of host peculiarity. Farmworkers, chemists, dry cleaners, electroplaters, garage employees, health care professionals, nurses, painters, printers, rayon makers, and others are among those who are exposed to hepatotoxins. The clinical manifestation of occupational liver disease might be acute/subacute or chronic, however, it is frequently mild. Some hepatotoxins have the potential to cause cancer.

What actions are being made to protect the liver from occupational health hazards?

Organising an Occupational Health Program:-

Occupational health programs are based on risk-based analysis and assist organizations in identifying and meeting all applicable legal responsibilities connected to worker health. It enables the identification of training and awareness needs based on proactive diagnostics such as periodic medical examinations and workplace monitoring reports.

● The occupational health programme consists of an Organisational structure with duties and responsibilities for top management, middle management, and the bottom line, which may include a medical physician, a safety practitioner, and so on.

● Health-care protocols and best practices that are applicable as a standard for Pre-employment medical testing, periodic medical screening, first aid records, cleanliness survey, workplace monitoring, and so on.

Program for Occupational Health Management:-

● To prevent occupational diseases, an occupational health management system must be created, implemented, and maintained by supporting safe and healthy working habits and ensuring a healthy work environment.

● Occupational health management entails developing, implementing, maintaining, and improving a health policy, organizational framework, health training, and education, occupational health hazard identification, risk assessment, and assurance of controls to prevent occupational diseases, various procedures for health promotion and social well-being enhancement, worker promotional activities and various improvement campaigns, addiction prevention programmes, pre-employer screening, and pre-employment screening. Look out for the best employee health management.

Occupational Health Management in the Workplace consists of the following components:-

Following are the Suitable and hygienic eating facilities:

● Rest spaces where workers can take a break and dine in a safe and hygienic environment. These places should have enough seats and be located away from potentially hazardous work areas, allowing workers to remove their PPE and rest.

● There must be food provisions so that food can be consumed in a sanitary atmosphere. If hot food and beverages are not provided at work, basic services can be provided so that employees can prepare their own hot food and beverages. To protect workers from second-hand smoke, non-smoking facilities should be offered.

Protection from exposure to extremes of temperature

First course of action should be to eliminate the need for workers to enter the extreme temperature environment. In cases where this is not possible, the environment can be controlled to lower the extreme temperatures. If these options are not possible, other checks should be recommended.

Protection from hot environment:

Protection from hot environments: Ensure ventilation in the workplace as moving air has a cooling effect, insulate and/or shield heat sources, provide easy access to drinking water or isotonic drinks, provide frequent breaks and job rotation, provide appropriate clothing for use in a hot work environment, but other workplace hazards must be considered.

Protection from cold environment:

Prevent or protect employees from droughts, shield/lag on particularly cold surfaces, provide suitable PPE such as insulated jackets, pants, boots, balaclavas, etc., provide frequent breaks and task rotation, and make hot food and drinks easily accessible.

In various sorts of environments, workers should be provided with information, teaching, training, and supervision so that they understand the health repercussions of the environment and the early warning indications of problems.